Waste and Cost Reduction by Reprocessing Used Motor Oil into a Synthetic Diesel Fuel

- Dr. Kevin Shurtleff, Austin Bettridge, Kyle Sweetman, Mung Nam Ng, Ryan Bernal

- Utah Valley University, College of Science, Department of Chemistry

- *Correspondence author: kshurtleff@uvu.edu, 801-360-0799

Waste Motor Oil (WMO)

- Utah Valley University (UVU) has an abundance of waste motor oil (WMO) from the airplanes, motor vehicles, and utility vehicles operated by the University.

- UVU produces over 500 gallons of waste motor oil (WMO) each year.

- Outside vendors were paid to dispose of the WMO.

- Mario Markides of the Aviation Science Department initiated this project to reduce WMO disposal costs.

WMO Regulations

- Federal regulations allow a generator of WMO to reprocess and use it with the organization(1).

- UVU has a fleet of diesel utility vehicles that can use the synthetic diesel fuel produced from WMO.

- The objective is to repurpose the WMO generated on campus into synthetic diesel fuel using a cost-effective, scalable process developed by our team.

Motor Oil

- Motor oil is a fraction of crude oil containing long-chain, branched and cyclic hydrocarbons averaging 20 carbon atoms.

- Diesel fuels is a hydrocarbon fraction averaging 15 carbon atoms.

- Gasoline is a hydrocarbon fraction averaging 8 carbon atoms.

Crude Oil Factional Distillation – Fractionating Column diagram

Crude Oil heated to:

- Bitumen > C70

- 300 degrees C: Fuel Oil C50 – C70

- 350 degrees C: Lubricating Oil C20 – C50

- 250 degrees C: Diesel Oil C14 – C20

- 200 degrees C: Kerosine C10 – C16

- 120 degrees C: Naphtha C8 – C12

- 50 degrees C: Gasoline/Petrol C5 – C10

Motor Oil Composition

- Base oil (C18 -C34, Polyalphaolefins (PAOS), Esters, Alklated Naphthenes (ANs)) – 80-90%

- Motor oil additives (3,4)

- indeed improvers (large polymeric molecules)

- dispersants (polyamines, surfactants)

- detergents/neutralizing agents (calcium, magnesium, and sodium sulfonates, phenates, and salicylates).

- friction modifiers (very polar esters and partial esters)

- seal conditioners (esters)

- corrosion inhibitors (zinc dialkyl dithiophosphate)

- anti-oxidants (phenols and amines)

- pour point depressants (polymeric molecules)

- antifoams (silicone products)

- diluent oil (mineral oil).

Diesel Engine Hobbyists

- Hobbyists have been using WMO to fuel their engines for many years(2).

- Typically, hobbyists mix WMO with unleaded gasoline. The mose common mixture is 80 volume % WMO and 20 volume % unleaded gasoline (80:20)

- WMO is typically “cleaned” before using it as a fuel, in order to remove contaminants.

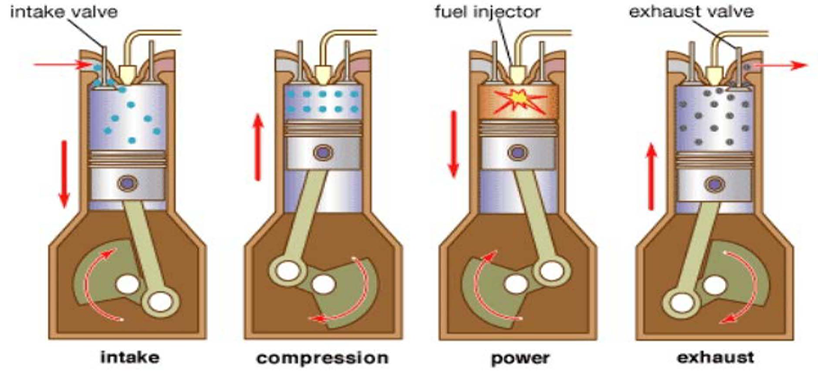

Diesel Engine Operation(7)

The intake valve allows diesel fuel to flow into the intake valve. The valve then compresses the fuel. The fuel injector sparkes the fuel giving the engine power. The exhaust valve releases the exhaust from the valve.