Waste engine oil is a kind of hazardous waste that is difficult to be naturally decomposed. According to the environmental protection department, once the waste mineral oil penetrates into the soil, the soil cannot be repaired for decades. To eradicate pollution, it is necessary to dig deep and remove all contaminated soil. If it penetrates into the groundwater, the consequences are unimaginable; if not handled properly.

The regeneration of waste engine oil is the removal of impurities in the oil by sedimentation, distillation, pickling, caustic washing, filtration, etc. It is a toxic substance and belongs to the solid hazardous waste marked by the state. Waste engine oil is strictly prohibited from being bought and sold at will, and should be disposed of by a qualified waste oil treatment enterprise.

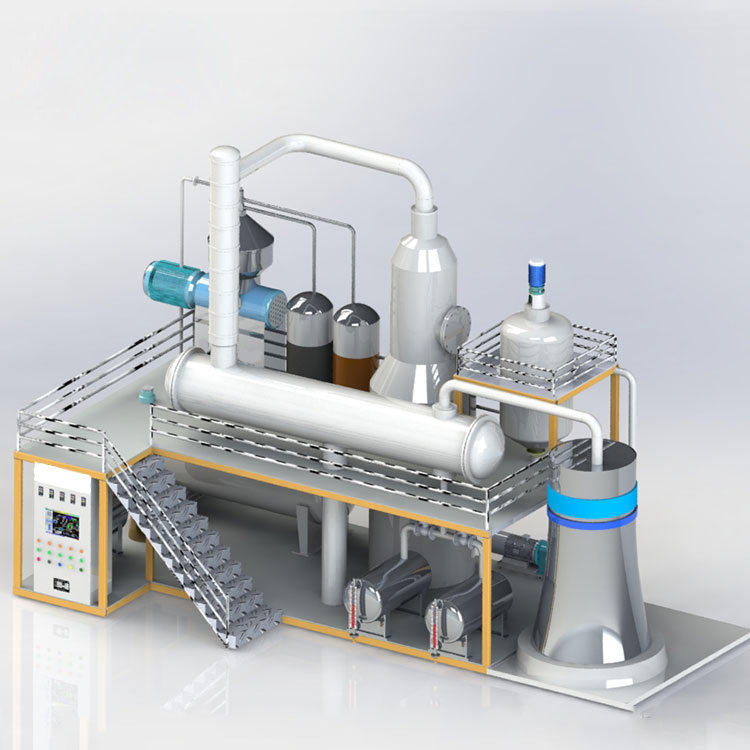

The waste engine oil can be recycled and processed through the following links, then the products produced can meet the national standards.

Steps: (1) Adding a special catalyst to the waste engine oil , catalytic cracking at medium temperature, the waste engine oil and various mineral oils can achieve the cracking effect;

- The gas component obtained after the cracking is further catalytically cracked in a fixed bed to obtain the oil vapor;

- Oil vapor is fractionated to collect gasoline and diesel fractions respectively;

- The fractions of gasoline and diesel are separately refined.

The whole process not only ensures the product quality, but also the equipment investment is simple, the volume is smaller, the process is simplified, and the production cycle is shortened through the device that removes impurities.

The waste oil needs to judge the availability of waste oil according to the oil environment, oil level and procedures. Good waste oil is very different from poor waste oil, and there are great skills in how to distinguish waste oil.

The basic identification of waste oil is no water. There are five major indicators that can be measured by methods such as “Four Diagnostic Methods of TCM”. The five indicators include moisture, color, impurities, density, and taste.

Moisture: The most important indicator of waste oil is to look at its water, which is what the waste oil people often say “there are several waters.” Moisture is generally caused by rain, improper operation or unsuitability of the operating environment. Usually the lower the water, the better, of course, the more expensive the price. At present, there are professional water measuring instruments in the industry. If you don’t know how to judge the moisture of the oil through common sense and experience, you can use the instrument.

When machinery and equipment are working, the oil is affected by the surrounding air, temperature, pressure, electric field, light and other factors due to long-term contact with the metal, The foreign matter is gradually added to the oil, and as a result, there are moisture, dust, sand, metal chips in the oil, and gradually oxidize in the long-term use, so that the chemical composition changes, and the deteriorated substances and harmful impurities are generated.

Precautions for waste oil regeneration

Pay attention to the following matters when recycling waste oil:

(1) Recycling of waste oil should be carried out in a centralized manner to avoid a small amount of dispersing work and prevent waste and heavy operation.

(2) Waste oil regeneration should be equipped with the necessary equipment, and should not be rushed to take risks when unconditional, so as to avoid danger.

(3) Do not overfill the oil during distillation to avoid fire from spilling oil. After the distillation oil temperature drops below 150oC, the residual oil can be released to avoid spontaneous combustion of the residual oil.

(4) Wear rubber gloves and safety glasses when handling, so as not to damage the body’s acid residue after treatment. It can also be buried as a fuel, but it can not be dumped.