What happens to your recycled used oil?

Used oil, or ‘sump oil’ as it is sometimes called, should not be thrown away. Although it gets dirty, used oil can be cleaned of contaminants so it can be recycled again and again. There are many uses for recycled used oil.

These include:

Industrial burner oil, where the used oil is dewatered, filtered and demineralised for use in industrial burners;

Mould oil to help release products from their moulds (e.g. pressed metal products, concrete);

Hydraulic oil;

Bitumen based products;

An additive in manufactured products; or

Re-refined base oil for use as a lubricant, hydraulic or transformer oil.

Once you have taken your used oil to your local collection facility, used oil collectors take the used oil and undertake some pre-treatment and recycling of the used oil or sell it to a specialised used oil recycler.

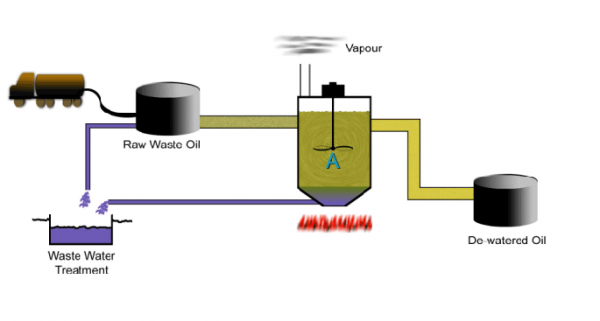

Pre-treatment or Dewatering

Pre-treatment of used oil involves removing any water within the oil, known as dewatering. One way of doing this is by placing it in large settling tanks, which separates the oil and water.

Further recycling steps include:

Filtering & demineralisation of the oil, to remove any solids, inorganic material and certain additives present in the oil, producing a cleaner burner fuel or feed oil for further refining;

Propane de-asphalting to remove the heavier bituminous fractions, producing re-refined base oil; and

Distillation to produce re-refined base oil suitable for use as a lubricant, hydraulic or transformer oil. This process is very similar to the process undergone by virgin oil.

Water is found in used oil as free water or bound water, for example in emulsions. The term dewatering is usually taken to mean the removal of free water. Where water has been emulsified with oil, the emulsion has to be “broken” with a demulsifier before the water can be separated from the oil.

Dewatering is a simple process relying on the separation of aqueous and oil phases over time under the influence of gravity. The used oil is allowed to stand in a tank (raw waste oil) and free water drops to the bottom where it can be drained, treated (wastewater treatment) and discharged appropriately to sewer or stormwater depending on the quality and local regulations.

Dewatering process

Heating and stirring the used oil in a tank (A) and driving off the water through evaporation can speed up the dewatering process.

The “dried” or dehydrated oil is then suitable for further processing or for use as a burner fuel.

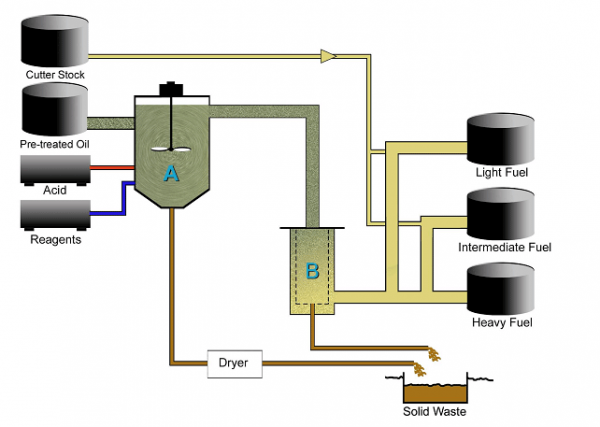

Filtering & Demineralisation

The purpose of filtering and demineralisation is to remove inorganic materials and certain additives from used oil to produce a cleaner burner fuel or feed for re-refining.

Used oil feedstock is transferred to a reaction tank (A) and mixed with a small quantity of sulphuric acid and heated to about 60oC. A chemical surface-active reagent, called a surfactant, is added to the reactor (A) and after stirring the mixture is allowed to stand. This allows the mixture to separate into two “phases” – i.e. oil and water-based or aqueous. The reagent causes the contaminants to accumulate in the aqueous phase, which settles to the bottom of the tank (A) and is drained off as slurry. This phase contains acid, used oil contaminants, including metals and some of the oil additives. The water is dried off, leaving a solid waste that must be disposed of.

Filtering and demineralisation process

The demineralised oil is filtered (B) to remove suspended fine particles (to solid waste) and run off to storage (C) as a clean burner fuel. It can be further diluted or “cut” with a lighter petroleum product (called cutter stock) to produce a range of intermediate to light fuel oils depending on the fuel viscosity requirements of the burner.

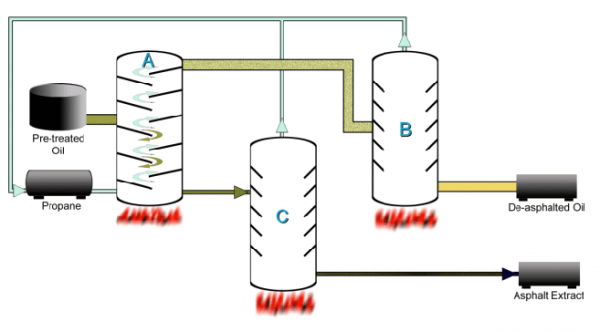

Propane De-asphalting

The Propane De-asphalting (PDA) process is an important pre-treatment step in the re-refining process producing de-asphalted lube-oil, which becomes a feedstock for the next step in a re-refining facility. The other output (which is also an input) is propane, which is recovered from both streams and re-used within the process.

The PDA process relies on the greater solubility of the paraffinic and naphthenic (ie essentially the base oil) components versus the contaminated waste material in a stream of propane.

Propane de-asphalting process

The separation of the lubricating oil fraction from used oil is a continuous process and is conducted at ambient temperature when processing used oil.

The used oil is pumped into the middle of the extraction column (A). Liquid propane is charged to the bottom of the column (A). The oil being heavier than propane flows down the column (A); the propane rises in a counter-flow thus mixing the input streams within the column (A). The rising propane dissolves the more soluble lube oil components, which are carried out the top of the column (A) with the propane, and the propane insoluble material is removed from the bottom of column (A).

Propane is vaporised from both streams [ie., the de-asphalted lube-oil stream (B) and the waste stream (C)] in “stripper” units (B) and (C), then condensed and returned to the propane storage tank.

The de-asphalted lube-oil component is feed for the next processing stage. The residuum (waste) component is mixed with bottoms from the vacuum distillation tower to produce an asphaltic material.

Distillation

Distillation (or Fractionation) is the physical separation of components of lubricating oil by boiling range. Depending on the type of distillation, the boiling ranges can produce gases and gasolines at the lower boiling points with heavy lubricating oils being distilled at higher boiling points. Distillation is the core process for a facility capable of producing re-refined base-oils to virgin base-oil quality.

There are 2 types of distillation, atmospheric and vacuum.

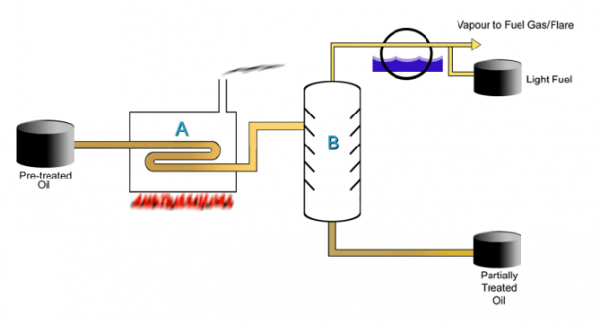

Atmospheric Distillation

Atmospheric distillation is generally (but not always) considered a pre-treatment step for vacuum distillation and does not require de-watered feedstock. Atmospheric distillation is carried out at normal atmospheric pressure and with temperatures up to 300°C.

Prior to the atmospheric distillation process, the feedstock can have undergone PDA treatment, but this is not an absolute pre-requisite.

Atmosphere distillation

Atmospheric distillation is a relatively simple process separating lower boiling point liquids at ambient pressure. Used oil is heated (A) and charged to a distillation tower (B). Lower boiling point hydrocarbons present in the used oil (eg gases, petrol and solvents) and water are collected at the top of the tower (B). Some of these hydrocarbons can be condensed and collected for use as a fuel in the refining process.

This process is only suitable for temperatures up to 300oC, as temperatures above this can lead to “thermal cracking” of the larger molecule (higher boiling point) hydrocarbons, ie. the actual lube oil molecules we are aiming to recover.

After atmospheric distillation, the oil usually undergoes vacuum distillation. Note that used oil can be sent directly from a “drying” process to a vacuum distillation unit without necessarily undergoing atmospheric distillation. However, it is generally accepted that water and lower boiling point hydrocarbon components be removed prior to vacuum distillation.

Vacuum Distillation

Vacuum distillation is considered the key process in used oil re-refining. If atmospheric distillation is utilised, the oil from the atmospheric distillation column is the feedstock for the vacuum distillation column. In vacuum distillation, the feedstock can be separated into products of similar boiling range to better control the physical properties of the lube base stock “distillate cuts” that will be produced from the vacuum tower products.

The major properties that are controlled by vacuum distillation are the viscosity, flash point and carbon residue. The viscosity of the lube-oil base-stock is determined by the viscosity of the distillate in terms of its relative viscosity separation, eg. light, medium and heavy oil.

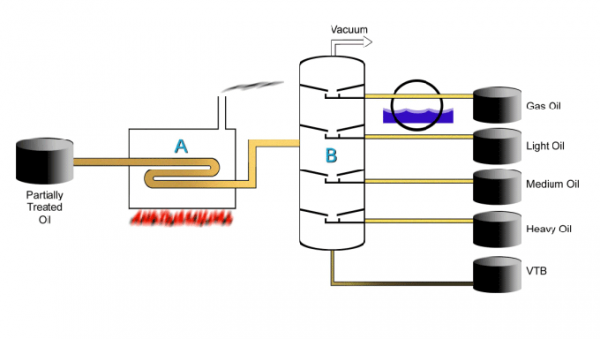

Vacuum distillation

The used oil feedstock (usually from the atmospheric distillation unit) is heated in a furnace (A) and flows as a mixture of liquid and vapour to the heated vacuum distillation column (B) where the vapour portion begins to rise and the liquid falls. Steam can be added to assist vaporisation.

A vacuum is maintained in the column (2-10 mm Hg) by a vacuum system connected to the top of the tower (B). By reducing the pressure, materials normally boiling at up to about 540oC at atmospheric pressure can be vaporised without thermal cracking.

As the hot vapours rise through the column (B), they cool and some condense to a liquid and flow back down the column. Similarly, some of the downward flowing liquids are re-vaporised by contacting the rising hot vapours. Special devices in the column allow this upward flow of vapours and downwards flow of liquids to occur continuously.

At various points in the column (B), special trays, called draw trays, are installed which permit the removal of the liquid from the column. If three cuts or “fractions” of oil are required to produce light, medium and heavy base stocks, then three draw trays are positioned appropriately. This can be reduced to two draw trays if, for example, only 2 cuts or fractions are required.

Some of the material does not boil even under this vacuum. This remains in the vacuum tower and is run out as the vacuum tower bottoms (VIBs). This material contains the heaviest molecules, including some lube oil additives and carryover contaminants not removed in the PDA process. (Note: not all re-refining plants have PDA units).